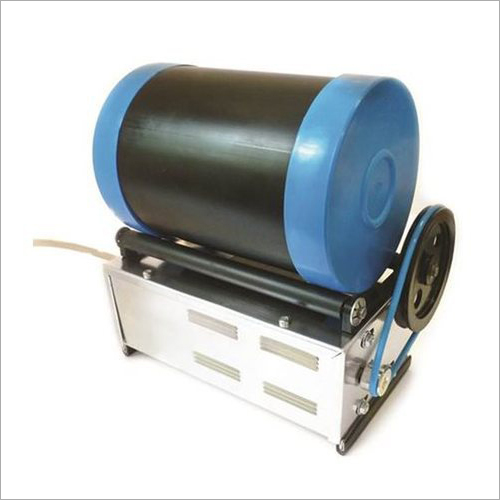

Barrel Polishing Machine

Price 2500000 INR/ Unit

MOQ : 1 Unit

Barrel Polishing Machine Specification

- Type

- Barrel Polishing Machine

- Material

- Mild Steel

- Capacity

- 40 - 80 Mesh

- Voltage

- 220-380 Volt (v)

- Weight

- 3.2 Kilograms (kg)

- Color

- Black and White

- Warranty

- 1 year

Barrel Polishing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 5 Units Per Day

- Delivery Time

- 15-20 Days

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- Main Domestic Market

- All India

About Barrel Polishing Machine

Our provided Barrel Polishing Machine is an optimum solution for all kind of finishing operations like debarring, descaling, edge rounding, smoothing and glaze finishing of machines, pressed, sintered, die-cast and heat-treated parts and products. This machine is designed to obtain an effective and speedy polishing of the nails. Our offered Barrel Polishing Machine is made under the guidance of our expert professionals and praised for their unique features like durability and corrosion resistance.

Versatile Polishing for Industrial Use

The Barrel Polishing Machine is engineered to cater to diverse polishing requirements in various industries. Its mild steel construction guarantees longevity, while adjustable mesh capacity supports precise finishing. With manufacturers, suppliers, and traders offering reliable support throughout India, this machine is favored for both new installations and service needs.

Reliable Performance and Easy Operation

Operating at 220-380 volts and weighing only 3.2 kg, the machine provides powerful yet user-friendly polishing solutions. The one-year warranty ensures peace of mind, making it a dependable addition to any industrial setup. The distinct black and white design enhances visibility and safety during operation.

FAQs of Barrel Polishing Machine:

Q: How does the Barrel Polishing Machine function for industrial polishing?

A: This machine rotates components inside a barrel with abrasive materials suited for 40-80 mesh, effectively polishing surfaces to a uniform finish. Its design facilitates thorough and even treatment, enhancing product quality.Q: What components or materials are ideal for processing with this machine?

A: Items made from metals, especially those requiring delicate finishing, are suitable for the Barrel Polishing Machine. Its perfect for small parts that fit its mesh capacity and benefit from consistent surface enhancement.Q: When is it recommended to use the Barrel Polishing Machine in manufacturing or service environments?

A: This machine is best utilized during the final finishing stages, prior to assembly or packaging. It ensures products meet aesthetic and functional standards before reaching customers or subsequent processing steps.Q: Where can I purchase or receive maintenance for the Barrel Polishing Machine in India?

A: You can acquire the machine and seek after-sales service from authorized manufacturers, suppliers, and traders throughout India. Service providers also offer regular maintenance and support based on warranty coverage.Q: What is the standard process for operating and maintaining the Barrel Polishing Machine?

A: Operation involves loading the barrel, setting voltage, and running the machine with suitable abrasives for the required mesh size. Routine maintenance includes cleaning the barrel, inspecting parts for wear, and ensuring compliance with safety protocols.Q: How does using this machine improve productivity and finish quality?

A: By automating the polishing process, the machine saves time and delivers consistent surface finishing, reducing manual labor and errors. Its efficiency leads to higher output and superior product appearance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Polishing Machines Category

Tumbler Polisher Machine

Price 30000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 3 to 1000 ltr

Color : Grey

Voltage : 110 Volt (v)

Material : Mild Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS